Ask anyone who’s worked with calibration gases before, and they’ll tell you one of the most annoying problems they run in to is component fade.

This happens a bit like magic, but instead of the magician producing a rabbit from a hat, he makes your 25ppm Hydrogen Sulfide mix slowly disappear. You are now the proud owner of a cylinder of Fancy Nitrogen.

Appreciate this guide? We'd really appreciate you purchasing your calibration gas from us!

But what happened to the gas? Did it disappear? Has it leaked out? Adsorption, absorption, self oxidation? You hear all these terms, but to be fair, when we gas people start to talk about it everyone gets a bit glassy eyed, and you’re as likely to hear one thing from a sales person on Monday as you are a totally different story on Tuesday.

So lets break down how calibration gas, and hydrogen sulfide (H2S) in particular, fades in a cylinder and screws up the calibration of your gas detector. I’m going to leave this post with comments on so scientists in the industry can correct me anywhere I’m wrong. I’m by no means perfect in my understanding here, and gas chemistry and reactions are a bit amorphous (ha ha), so I’m welcoming anyone to this post to comment and/or correct me. I’m grouping the causes for fade into 4 main categories. I’ll go over them each in detail and then put a few pointers on at the end for how you can keep the gas stable. Keep in mind we’re talking about sulfur reactive gases like H2S and SO2 in particular here, and that other gases like chlorine and nitrogen dioxide are monsters of a different breed.

Causes of Hydrogen Sulfide Calibration Gas Fade:

- Cylinders

- Valves

- Oxidation with Moisture

- Heat

Cylinders

The cylinder wall is the most obvious place anyone goes looking for reasons why H2S has faded. A whole host of things can go wrong here, including:

- Problem Metals

- Cleaning Procedures

- Insufficient Treatments and Conditioning

- Inefficient Surface to Volume Ratios

- Incorrect Cylinder Choice

Problem Metals

Starting with the basics, hydrogen sulfide reacts with copper, especially in the presence of even trace amounts of moisture. Most cylinders you buy for reactive gases (like 4-gas used in most gas detectors) will be made of aluminum alloy. What that means is it’s almost totally aluminum, but they add other elements to it to strengthen the structure of the metal. The most common of these is copper, but the metal components and percentages will vary. Sometimes you’ll get more copper, sometimes less. Aluminum cylinders are created essentially by taking a puck of aluminum and jamming a big piston through it in a process called extrusion. This stretches the puck out and forms it into a cylinder. Depending on the concentration of copper and how it is distributed within the metal, occasionally you’ll get pockets of copper which stretch out and are exposed through this process. This opens up an area on the cylinder that will be reactive to gases like H2S. The cheaper the aluminum used, the more likely you are to have these pockets that will then react the H2S out of your gas composition. Keep in mind, it doesn’t take much copper for this to be a problem, and with the tiny amount of H2S in your cylinder, even a few PPM drop will ruin your gas and calibration.

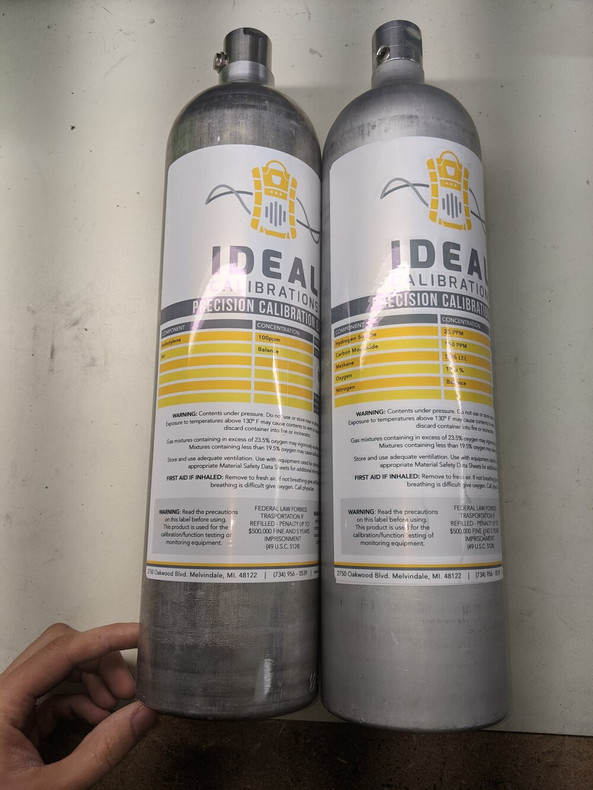

Over time, cylinder manufacturers have gotten wise to this problem and have started improving the quality of their cylinders. Most of the industry is currently in the process of moving from the old disposable cylinders to newer refillable cylinders. The difference here is that the newer cylinders are thicker and use better quality aluminum. Quality manufacturers of this product that I’m aware of include Luxfer, Catalina, and Metal Impact, though I’m sure there are others that we haven’t tested.

Cleaning Procedures

Think back to the process above with the aluminum puck and the punch. When that piston hits the puck and jams it through, the process generates heat and shears the metal. Heat and friction are enemies at this stage in the process, so cylinder manufacturers use a lubricant on the puck that smooths out the friction and dissipates the heat, just like you would have in an engine. The problem is that the lubricant doesn’t disappear. It sits around in the cylinder. Not only that, but depending on what lubricant is used, the process of jamming a huge high pressure punch through the metal, combined with heat and friction, can create what are called oligomers that are left behind as a reaction. Wonder upon wonder, H2S reacts with these oligomers. Some companies wash these cylinders out, some don’t, and the cleaning process in general reuses old cleaners for months at a time. Needless to say, it isn’t an efficient process for cleaning at a serious level. Imagine washing the floor with the same mop water each day. It might clean it a bit on the surface, but at the level you need to keep 0.00025% of a gas mix stable, it just isn’t enough.

Thankfully, in the last few years cylinder manufacturers have wised up, and they’ve been creating products where the cleaning solution is changed out much more frequently and the cylinders are given better inspections. This of course raises the price, but it’s well worth it if you want a stable product. Unfortunately, these procedures are still a bit new to the industry, and occasionally you’ll get cylinders that still have some of the cleaning product stuck inside. It’s a situation that’s gotten better but is by no means perfect.

Insufficient Treatments and Conditioning

What are gas manufacturers to do when their cylinders may come with small streaks of copper they can’t see and microscopic oligomers stuck on the cylinder wall? How do you keep the gas inside from touching the walls of the vessel? How do you react out the moisture that is microscopically stuck in the aluminum of the cylinder wall? You coat the inside of the cylinder or try and inert the reactive surface.

This has taken a number of different forms in the industry. Part of the problem is that with aluminum cylinders you can’t heat them up high enough to drive off the trapped water. The main solution we’ve seen is a process called silanization. Essentially, you take silane gas (or trichlorosilane) and dump it into the cylinder. Silane reacts with the cylinder wall when it is heated to a high temperature and does two things: It reacts out the moisture and leaves behind a glass-like layer of inert silicon. The problem is that this process, while extremely effective at temperatures around 450 degrees Celsius, is nowhere near as effective at low temperatures and pressures and aluminum cylinders can’t handle the temperatures necessary. However, it’s the best they had for getting the moisture reacted out even though they weren’t able to heat it up enough to create the silicon bond. Other methods involve “pickling” the cylinder with high levels of gas at different temperatures, polymer coating, and mechanically or chemically polishing the cylinder internally.

These methods all help, but to truly inert a cylinder you end up with very high costs. To my knowledge, no one has a really fool proof system here, and there’s plenty of room for innovation in the industry.

Inefficient Surface to Volume Ratios

Something to keep in mind is that the smaller a cylinder gets, the harder it is to keep stable. This is because the ratio of how much gas volume you have in a cylinder shrinks and the surface area of the inside of the cylinder doesn’t change as much. You can pretty easily decrease the volume of gas by half, but only lose 20% of the internal surface area of the cylinder. This means your risk factor for the gas goes up because you have all the problems mentioned above and now you have even less molecules of H2S bouncing around to keep stable. Your cylinder wall reaction will affect quite a bit larger percentage of the gas inside.

Takeaway here is to remember that the bigger the cylinder, the easier it is to keep the gas inside stable. Be very wary of micro cylinders you see being sold. We recommend sticking to the established 116L, 58L, and 30-34L sizes in the industry given the current state of cylinder treatments.

Incorrect Cylinder Choice

At least a few times a year we hear from customers using small aerosol cylinders having problems with their monitors. Often you’ll hear these cylinders referred to as “bump gas” cylinders. These cylinders are made from extremely cheap materials, and keeping anything reactive in them for any length of time leads to problems. Manufacturers of gas in these cylinders often label them for +/- 20% of the given values and then fill them with high levels of H2S to hide fade. NEVER use these cylinders for calibration. If I had my way they wouldn’t even be available for bump testing. Yes they’ll fulfill the functional bump test requirements of showing that the sensors detect gas, but far too often we hear of distributors trying to sell this gas as calibration gas or customers trying to use them for calibration because they don’t know any better and don’t have anything else available.

Bottom line: avoid aerosol bump gas cylinders like the plague. They’ll do you wrong eventually, it’s just a matter of time.

Valves

Second in line for things that can go wrong on a calibration gas cylinder and cause fade: valves. It’s a much smaller surface area within the cylinder, but potentially the hardest problem to solve. Most manufacturers buy these valves in huge lots and inspecting them for quality on receipt is a difficult prospect. Before we get into what can go wrong, lets break the valve down. The valve fitting is called a “C10” fitting. Why is it not called a “CGA-something or other?” No idea and so far I haven’t found anyone who can tell me, so if you know shoot me an email. Valves come in a few different materials and have different safety relief devices, and there are pros and cons to each one.

Materials

Materials in valves matter because it’s all potential surface area for the gas to react with. To that end there are a few different standard materials used in cylinders.

- Brass - Used primarily in steel cylinders for non-reactive blends, not for use in cylinders meant to store reactive gases

- Nickel Plated Brass - Cheapest and most common. Problems can occur if the plating company goes cheap or has an error. Watch out for foreign valves as we’ve seen some quality problems for manufacturers outside the US

- Aluminum - Good for reactivity but causes problems on valving/devalving if the threads burr

- Stainless Steel - Good for reactivity, valves well, more expensive

Of the above, we use stainless steel for our reactive mixes. It’s not that the others are bad, but the likelihood of having a quality failure is lowest with stainless steel from what we’ve seen.

Safety Relief Device

Safety relief devices on valves are there to protect you if cylinder pressures get too high. They open up to allow the gas to escape instead of blowing a hole through the side of the cylinder. Occasionally valves will use a combination of two of these, but we don’t see it commonly. Pros and cons of these styles of safety relief device are:

- Thermal Plug - the cheapest and most common safety relief device. It works based on the heat of the cylinder combined with the pressure. Essentially as the cylinder heats up due to the increase in pressure, the heat softens the lead solder which allows the pressure of the cylinder to push it out of the valve, releasing the gas. The problem with this method is that the lead solder used to hold the plug in place can react with your gas. You’ll see this as a green discoloration on the solder port if you devalve the cylinder and flip the valve over

- Frangible Disk - Frangible disks are small scored pieces of metal that rupture at a given pressure. They come in different pressures, and the grades of metal are generally lower in quality. Any time you have a low quality metal potentially in contact with your gas you have potential for an issue

- Spring loaded - These are only found in lower pressure steel 17L and 34L cylinders with a CGA-600 fitting. You should never see one of these on a valve used for reactive components. This is a resealable spring that pushes open to vent pressure at a given level. They’re generally made of decent materials, but they can occasionally fail to vent or vent too soon. They also don’t show you if a release occurred, so if you had a cylinder in a hot truck it could potentially release and reseal without your knowledge.

This is an area we think manufacturers of valves could show some real progress. Coating the parts in the safety relief device may go a long way to stabilizing the interface for reactive gases, but so far no company to my knowledge offers a safety relief device with an inert coating.

Lubricants

Valves are put together by hand and have small moving pieces. To get everything assembled properly they use a lubricant that is generally rated as safe and non-reactive. However, you’ll see problems if the manufacturer used too much lubricant that day or didn’t wipe off any extra. This is because the gas, while not reacting with the lubricant per say, still gets stuck in the liquid.

The best solution for this involves the valve manufacturer implementing proper procedures to clean the valves before shipment and advising their employees to make sure they don’t slather the valve in lubrication while they’re putting it together.

Oxidation with Moisture and Oxygen

Self oxidation is the process where H2S reacts with oxygen present in the cylinder. It’s a nasty problem in that you can’t control for it once it starts. You can have the best cylinder in the world, the cleanest valves, and the most accurate addition ever and it won’t matter at all. It’s horrendously hard to test for or prevent, but here is what we’ve learned about fighting it: KEEP MOISTURE OUT OF YOUR CYLINDERS. What you’re trying to avoid is an acceleration reaction where freed H2S reacts with the moisture and begins dropping sulfuric acid in your cylinder. This reaction starts very slowly, but once it gets going you’ll be able to watch your H2S fade accelerate over time.

Moisture is the enemy. To combat this we recommend ALWAYS opening your regulator valve before screwing it into your cylinder. Why? Because there is a small space in the valve stem and in the regulator. When the valve on the regulator is closed, this creates a small chamber for the gas from that is trapped to mix with your cylinder. Room air naturally has moisture, and this effect will cause tiny amounts of that moisture to enter your cylinder. The procedure is to open the regulator valve, screw it into the regulator, wait till you hear the sound of the gas hissing through the regulator, then close the valve on the regulator and finish screwing your regulator in to the cylinder.

This effect is why you most often see single component hydrogen sulfide mixes done using nitrogen as a balance gas instead of air.

Heat

Final problem we’re going to go over is temperature. High Temperatures increase pressure in the cylinder (don’t stick them in an oven… or leave them in a hot car in the desert) and causes reactions to accelerate. Obviously, making reactions in the cylinder happen faster will cause a problem because it means your H2S fade happens faster. In the industry we use heat to accelerate conditioning in the cylinder. You as the person using calibration gas want to avoid mimicking this process. You’ll also want to avoid low temperatures with calibration gas cylinders, but that’s due to other components commonly found in calibration gas, not necessarily having to do with H2S reactions.

The best solution here is to keep the gas around room temperature. Don’t store them in hot cars, cold cars, ovens, or igloos.

Conclusion

Keeping H2S stable is a huge pain in the industry. It hasn’t been solved yet, and I don’t see it all being solved overnight, but we’re doing our best to eliminate fade and keep the gas stable. New innovations are happening all the time, and our research department spends a lot of time testing new methods to keep H2S stable. If you have any ideas, drop us a line, we’re happy to hear them!